Walt Thompson has answered the call for old photos of the San Diego Kite Club. He has come up with some old fashioned 35mm prints and negatives which the WebApprentice has now scanned. While we don’t have room for all of them here are some select photos from the mid 1990’s.

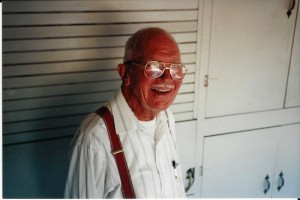

Virgil Dalton, an SDKC founding member, was famous for his pocket sled kites and his rotating windsocks. Here are some pictures from a windsock workshop he gave in September 1997 at a club meeting. As Walt notes, at this time in his life Virgil had virtually no feeling in his hands and had to be very careful, but he could sew beautiful kites and windsocks. Every stitch and cut perfect.

If you want Virgil’s pattern for these windsocks see thekitedude/Rick Spurgeon/WebApprentice. (We all fit in the same shoes.)

All photos clickable for a larger version.

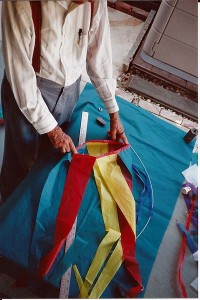

Parts needed for a windsock – white – need six of these; purple and red – need one of these to sew the segments into; light blue – three of these with an eyelet as a ‘bridle; weedwacker line to give the windsock shape.

Six segments to make a windsock, usually two or three colors. These are sewn into the leading edge piece, just be sure the tips touch and they are all lined up in the same orientation.

All segments sewn in, now you can cut your leading edge to size. Not sure if Virgil sewed the leading edge closed at this point or after the segments are sewn together, I have always sewn the segments first and then closed the leading edge.

Here all the segments have been sewn together and the leading edge joined together. This is actually easier than it looks. Only the last seam joining the first and last segments together is tricky. That is when all the twist comes in.

Now all the ‘bridle’ segments have been sewn to the leading edge and an eyelet put in. A little tricky but just take your time to get things even. Some line and a swivel are added to the eyelet so the windsock can rotate.